|

|

Bowlers Reference

Dual Angle Ball

Layout Technique

|

|

|

Developing an Understanding

This discussion is not intended to make you an expert ball

driller. The objective is to enhance your understanding of ball layout

considerations and more effectively communicate with your ball driller. A

second objective is to enhance your ability to make better choices as you create

an arsenal of equipment that best matches your bowling style and lane

conditions.

When a bowler purchases a high performance

ball, it is only the first step. If the ball is to perform

as expected, the pro shop measures the bowler's hand

to match the bowler's physical characteristics and capabilities. Equally

important, the technician fits the ball to the bowler's hand and accurately

tailors where the gripping holes are placed on the ball in order to match

bowler's style with the expected lane conditions. An effective ball layout

includes an accurate analysis and matching of the ball physics, the lane

conditions, the bowler's style, and the intended ball reaction. Each

bowler and ball is unique, and if the end result is to be effective, the fitting

and the ball layout is important.

It is the bowler's responsibility

to provide accurate information and data. The pro shop

technician relies on data that accurately matches the ball to

the bowler's style and objectives. The driller

interprets bowler-supplied data and the driller's

understanding to

determine an appropriate ball layout. We have covered

hand fitting techniques in other discussions, and now it is time to use this information and data. While there

are a variety of ball layout methodologies, the most

accurate method is through the use of a technique called the

Dual Angle Layout Technique.

The

Dual Angle Layout Technique is based on the physics of the

ball and the bowler's style and objectives. In this

discussion, our objective is to provide an understanding of

how layouts affect your equipment.

Since our focus is on the layout of the ball, it is first

assumed hand fitting task is known, as well as the bowler

unique Positive Axis Point (PAP) measurements. If not, you are encouraged to review

the Fitting section of this document. Also assumed is

an understanding of ball motion as it moves down the lane in

a Skid, transitions from the Skid into a turn or Hook, and

finally Rolls into the Pins.

The

Dual Angle Layout Technique breaks a layout down into three

measurements:

-

The Drilling Angle

-

The Pin to Positive Axis Point (Pin-to-PAP) distance

-

The Vertical Axis Line (VAL) angle

Each measurement has an affect on

ball motion. In addition, the relationship between

these three measurements affects ball reaction, so all three components

and their relationship to one another are important to the

final result. Let's lay out a ball, using the Dual

Angle Layout Technique,

and discuss each component separately. Afterwards, we

will discuss their interrelationship, and how they affect

ball motion as a whole. The technique begins from a

baseline which establishes the starting point for laying out

a ball.

|

|

If you were to roll an asymmetrical ball along a flat

surface, it would eventually roll with the core of the ball either

end-over-end (over the position pin) or along a lateral path (with the

position pin at the axis point). Typically, a bowling ball layout

favors the end-over-end path, and it rolls around it's Positive Axis

Point (PSA, or sometimes called the Mass Bias (MB) point.

The Ball's Preferred Roll

is over the Position Pin, and around an axis referred to as it's

Positive Spin Axis (PSA), sometimes referred to as the Mass

Bias point (MB). When creating a ball layout, these two

points (the Pin and PSA) are used as our reference points since this is

the preferred roll of the ball as it rolls toward the pins.

|

|

|

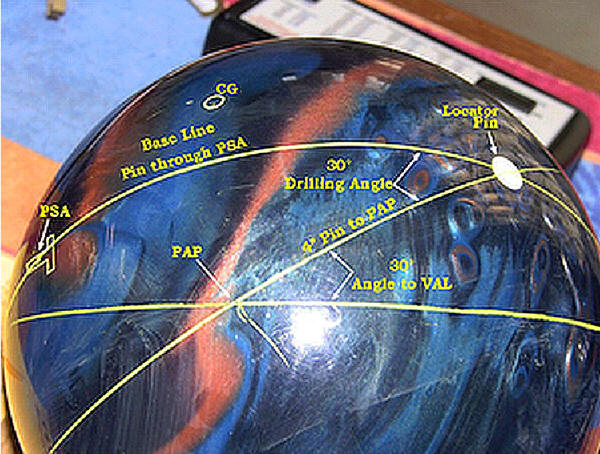

Reference Points

The ball layout is in reference to two points on a bowling ball.

Asymmetrical Ball

The ball is laid out in reference to a line drawn from the Position

Pin and the PSA since the ball core characteristics are unbalanced.

Symmetrical Ball

The ball is laid out in reference to a line drawn from the Position

Pin and the Center of Gravity (CG) in a symmetrical ball since the ball

is balanced and has no preferred spin axis. After a ball is

drilled, all balls become asymmetrical

The line drawn from the Pin and extending through the PSA or CG forms

the layout Base Line.

|

|

|

A line drawn from the

Position Pin allows us to more precisely place the position where the

gripping holes are placed in relationship to the Position Pin. The

angle formed between the Base Line and the drawn line is referred to as

the Drilling Angle. The Drilling Angle, affects the length

of the skid phase of the ball. The higher the drilling angle,

the longer the skid phase of the ball. The smaller the drilling angle,

the quicker the transition into the hook phase of the ball. The

drilling angle limits are 10°-90°

|

|

|

The PAP represents the Positive Axis

Point, or the initial axis of ball rotation as it is

released. The PAP is the reference point for ball

layouts. The Pin to PAP distance (Pin Length) dictates how much flare

potential the ball will have as

it travels down the lane. The more the ball flares, the more

fresh parts of the surface contacts the lane, and the more the

ball ultimately hooks. Flare Potential, is determined by the

Total Differential of an undrilled ball. Ball

manufacturers measure and publish the ball's total

differential (Diff). The higher the total differential, the higher the flare potential.

The lower the total differential, the lower the flare

potential. The maximum allowed total differential is

0.060" as set by the USBC. The Pin to PAP distance

determines how much of that flare potential is used.

The Pin to PAP distance can range from 0"

to 6.75". The maximum flare is achieved with a Pin to

PAP distance

of 3 3/8″. Think of the circumference of the

ball as approximately 27". Half way around the ball is

27"/2 or 13.5" (180°). One quarter around the ball, or

90°, is equal to 13.5" / 2 = 6.75". 1/8th the

circumference, or 45°, is 6.75" / 2 = 3.375 or 3 3/8".

This is the most unstable position of the ball, or the area

having the maximum flare potential.

A measured distance from the Pin defines the Positive

Axis Point (PAP) location.

The Pin to PAP distance

affects the percentage of the flare potential available; the length

and total hook.

The Locator Pin to PAP

distance limits are 0"-6.75".

Stable location - The Pin is located on the PAP (0"

Pin-to-PAP).

As you increase towards 2 3/4", flare increases, so

the ball typically hooks more overall.

Shorter distances

results in more boards covered in the hook such as heavier volumes of

oil.

Between 2 3/4" and 3

3/8", the ball retains axis rotation longer and thus comes off the break

point harder. The maximum track flare is equal to maximum

traction. Higher flare decreases total length and

increases the total hook of the ball.

Between 3 3/8" and 5",

the ball comes off the break point slower, but still strong.

Medium distances should be used for medium volumes of oil, but still

hook. Lower flare increases total length and lessens the total

hook of the ball.

At greater than 5",

the ball loses axis rotation quickly and thus is very flat off the spot.

Largest distances should be used to play straightest, because the ball

will not recover on inside to outside angles. |

|

|

The Angle to

the Vertical Axis Line (VAL)

The Vertical Axis Line (VAL) is a line

that passes through the bowler's Positive Axis Point (PAP)

and Negative Axis Point (NAP) when extended completely

around the ball. The VAL separates the top and bottom

of the ball on the bowler's initial axis of rotation.

It is parallel to the bowler's grip centerline, and

perpendicular to the midline. The VAL is used to

establish the placement of the gripping holes.

The Vertical Axis Line (VAL) is

established by drawing a line through the PAP at a

predetermined angle (the VAL Angle). The VAL angle

should be no less than 20° nor more than 70°, and determines how quickly the ball

will transition from hook to roll; how long the

ball remains in the hook phase.

Minimum 20° angle causes the

ball to rev up quickly, and transitions fastest from the breakpoint into

the roll.

Maximum 70° angle

results in the ball to rev up slowest, and transition slowest from the

breakpoint into the roll.

Smaller Angles to the VAL lowers the Radius of

Gyration (RG), and increases the total differential of the ball. This

results in the ball revving up faster and transitioning faster from the

hook into the roll phase of the ball.

Larger Angles to the VAL raises the RG, and decreases

the total differential of the ball. This results in the ball revving up

slower and transitioning slower from the hook into the roll phase of the

ball.

|

|

|

- The Drilling Angle affects the length of the skid

phase of the ball. The higher the drilling

angle, the longer the skid phase of the ball. The

lower the drilling angle, the quicker the transition

into the hook phase of the ball. The drilling

angle limits are 10°-90°.

- The Angle to the VAL affects how quickly the ball

transitions through the hook phase of the ball; how long

the ball remains in the hook phase. The Angle

to VAL limits are 20°-70°. Smaller angles rev up

faster and transition faster from hook into the roll

phase of the ball.

- The Locator Pin to PAP distance affects the

percentage of the ball's flare potential available;

the length and total hook. Lower flare

increases total length and lessens the total hook of the

ball. The Locator Pin to PAP distance limits are

0"-6.75".

|

|

|

Locating the

Gripping Holes The Midpoint of the Gripping holes are located in

relationship to the VAL and PAP. All accurate drilling techniques

measure from the PAP back to the Midpoint of the grip using the vertical

and horizontal components of the bowler's axis coordinates determined

during the bowler's fitting.

The Grip Center Line is parallel with the VAL. It is placed by

drawing a Mid-Line which is perpendicular to the VAL.

A point is placed along the VAL using the bowler's

vertical axis component and measured from the PAP.

The Mid-Line is drawn from that point and

perpendicular from the VAL. Using the bowler's horizontal axis

coordinates, the Mid-Line extends from the VAL to the bowlers Center

Line. This point is the mid point between the thumb hole to the bottom

edge of the finger holes.

The gripping holes are located along the Center

Line as determined during the bowler's fitting.

|

|

|

How

quickly the ball transitions from skid to hook to roll can be shaped

using the sum of the drilling angle and angle to the VAL. The sum of

the angles determines how quickly the ball transitions from skid to

hook to roll. The smaller sum of the angles changes more quickly.

The shape of the breakpoint is established by the

ratio of the drilling angle to the angle to the VAL. The larger the

ratio, the later the transition, and the sharper the breakpoint … more

back end.

The smaller the ratio, the sooner the ball transitions

into a roll.

If the sum of the two angles is small, the ball will

transition quickly. If the sum of the two angles is large, the ball will

transition slowly. The sum of the angles should be restricted between

30° and 160° to be effective.

The drilling angle should be 10° - 90°, and the angle

to the VAL should be 20° - 70°

|

Small Angle Sums (30-80) should

be used for:

Long oil patterns (>42')

Higher volumes of oil on the lane

Speed dominant bowlers

High axis tilt bowlers |

High Angle Sums (110-160) should

be used for:

Shorter oil patterns (< 35')

Lower volumes of oil on the lane

Rev dominant bowlers

Low axis tilt bowlers |

|

Medium Angle Sums (80-110) should be used when revs and speed

match, and medium oil patterns (36'-40') |

|

|

|

Measurement is the first step that leads to control

and eventually to improvement.

If you can't measure something, you can't

understand it.

If you can't understand it, you can't control it.

If you can't control it, you can't improve it." |

|

Thanks for visting

|